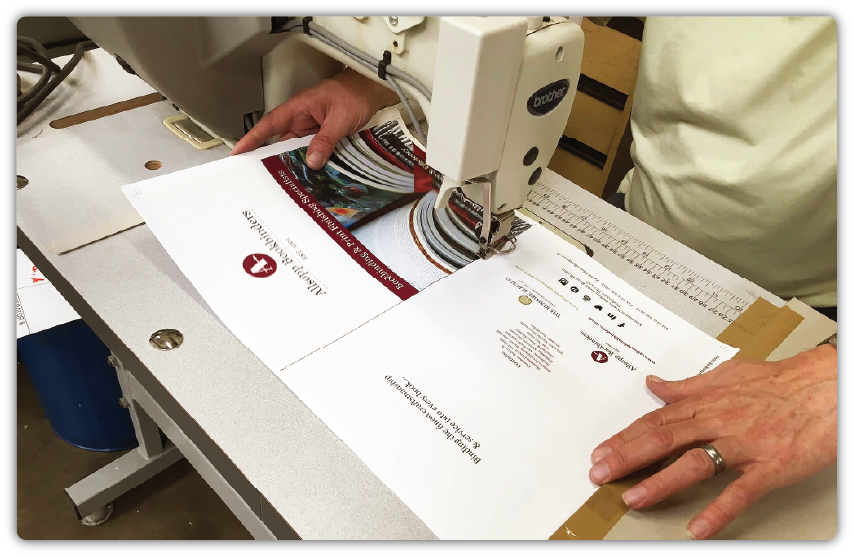

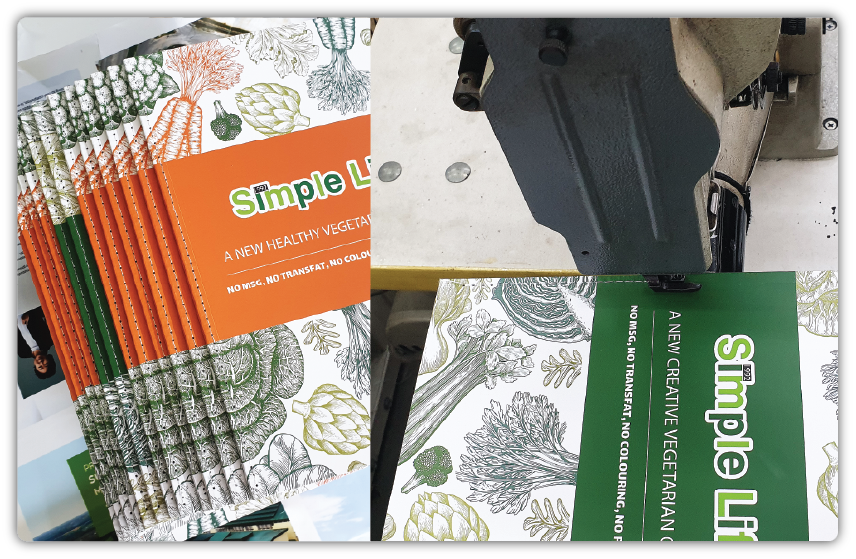

We provide comprehensive handbag manufacturing services from design conceptualization to production to meet the needs of different customers.

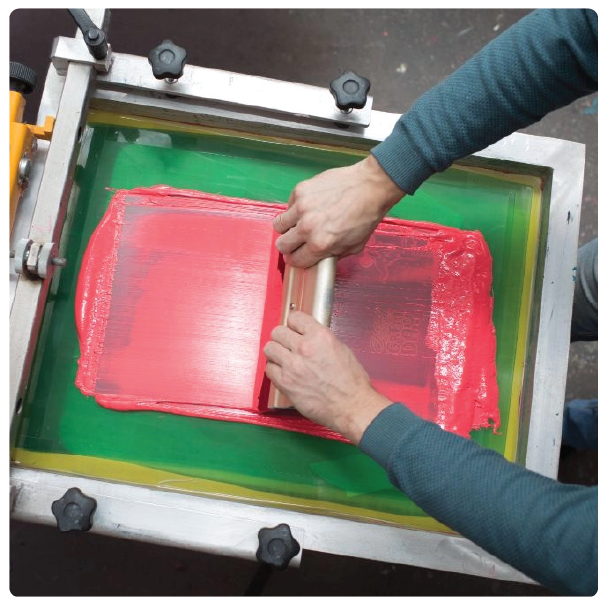

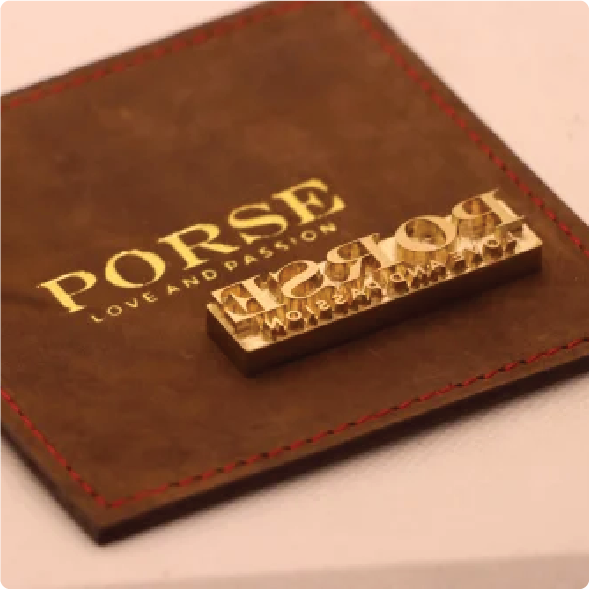

There are numerous ways to imprint onto your products to help spread Brand Awareness and Build Client Relationships. Understanding different imprint methods will help you communicate better to produce the best results!